Our Services Always Go The Extra Mile

OEM Available

We support any form of OEM customization requirements

Quick Shipping

We ship your order with 30 days

Quality Control

We test our products three round before shipment

FAQ

How do you guarantee your products quality?

products are guaranteed for a period of 1 years . The guarantee condition is any performance failure occurs within warranty period caused by non-human damage. There is no charge for replacing or repairing defective products.

What is the delivery time for new order?

it takes around 20~40 days, including purchasing raw material.

What payment methods can we use?

telegraphic transfer( TT), LC

What is the MOQ?

50 meters for Fabric belt, 200 meters for ST belt.

How long will it takes to receive the products after payment?

it takes 20~40 days for production, plus 10~40days transport time

Are you manufacturer or trading company?

we are trading company. I have a bro their factory producing the product. I do not want to cheat you, but I’m sure there are a lot of manufacturers’ price higher than ours.

We have been working in this industry for many years, and we met some bad manufacturers, some high-pricing ones, some poor-responsibility ones, some often-delay-delivery ones. You can meet everything if you work with Chinese manufacturers. We focus on this fields for years and we changed many unqualified manufacturers and spend much time on selecting good manufacturers. We hope you could feel happy to work with us, and we will prove our value in the cooperation.

Whether to carry out quality inspection after production is completed?

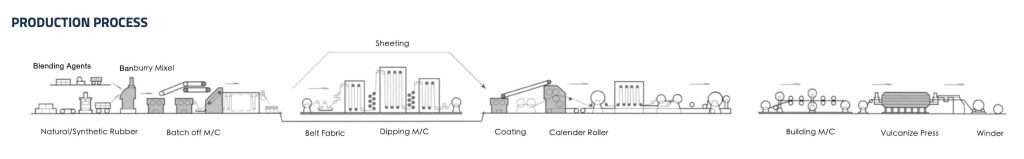

We have a serious quality control system. From raw material purchasing, all suppliers must pass the inspection of QC and all the records are made in the archives management system. The related test will be done when each bag of raw material received by us according to GB/International standards. Raw material can be stored only all test data reach related standards, otherwise related material will be returned back and related supplier. During the production process control management will be seriously executed. Strict processing techniques and inspection criteria are used in each step during production, which makes sure self-checking a mutual inspection can be executed in mixer, calendaring, forming, and vulcanization process. then unqualified semi-finished products can be controlled during production.

Can the product be customized?

All our products can be made to order and we can even develop new formula grades.