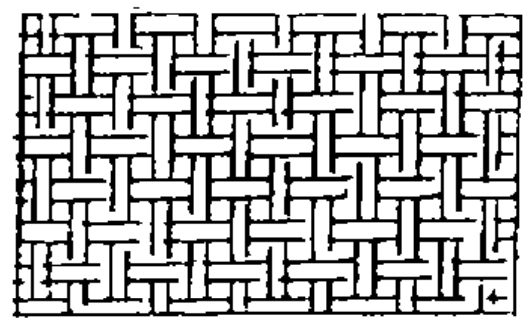

Plain Weave

The common structures of conveyor belt fabrics include plain weave, cord, straight warp, overall weave, and twisted pattern. The plain weave structure is the traditional structure of conveyor belt fabrics. It is used in large quantities and has a wide range of applications. Its structural feature is that the warp and weft lines are interlaced up and down, and there are many intersections. There are structural weaving,weaving waves increase the elastic elongation of the fabric, which is beneficial to the longitudinal flexure and transverse groove formation of the conveyor belt but leads to a greater decrease in strength. Commonly used plain weave fabrics, in addition to cotton canvas, there are EE, polyester (EP), and nylon (NN), with warp strength ranging from 50 to 630kN/m.

Cord Structure

Compared with the plain weave structure, the cord structure has higher warp strength and few weaving waves. The conveyor belt produced by it has good running straightness, small elongation, and bending fatigue resistance, so it is often used to manufacture short center distance endless belts. However, the tear resistance of this structure is poor. Adopting aramid cord structure and reinforced with nylon cord transversely, high-strength aramid cord structure conveyor belts can be produced. The strength include 630, 800, 1000, 1250, 1600 and 2000KN.

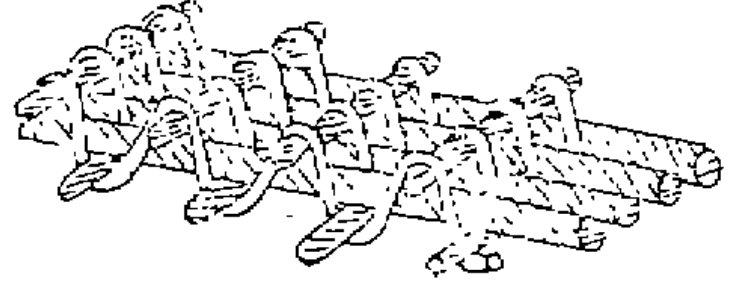

Straight Warp

The straight warp structure is composed of three parts: the main warp, braided warp, and weft. The warp and weft do not cross, and the braided warp acts as a fixed connection. The most important feature of this structured fabric is a high strength, low elongation, impact resistance, and tear resistance, and is more suitable for manufacturing single-layer and double-layer belts. The conveyor belt with a straight warp structure as the carcass has a simple production process and superior performance. Therefore, a straight warp structure is the development direction to replace a plain weave structure. Representative specifications of straight warp structure are EP200, 250, 315, 400, 500, 630, 800, 1000, 1250, 1400 and 1600.

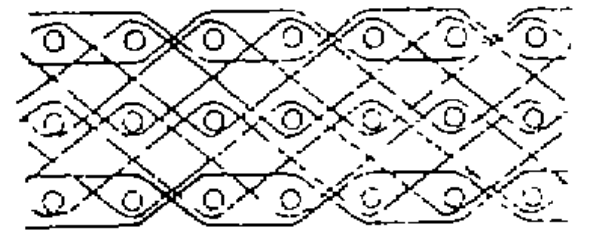

Overrall Weaving

The overall weaving is multi-layer interweaving. The composition can be divided into three parts: warp, weft, and overlap. The weft threads are 2 to 5 layers, in a straight state, the warp threads are interlaced up and down diagonally, and the overlapping threads are cotton threads. The weft yarns are mostly nylon, and the warp yarns can be nylon, polyester, and aramid according to the strength requirements. Both the weft and the warp are equipped with about 30% cotton yarn to improve its adhesion with the PVC paste. The cotton yarn also has a flame retardant (absorbs the melt of nylon and polyester) and a cushioning effect. The overall woven structure has high density and loose organization, which can produce heavy-duty fabrics with large thickness and high strength, which can be used to produce flame-retardant conveyor belts used in coal mines. The overall woven structure has strong integrity, flexural resistance, and impact resistance, the mechanical joint has high strength, and its tensile strength is between 400 and 4000KN.

Twisted Structure

The fiber arrangement in the twisted structure is very loose, the strength of the weft is high, and the warp is only used for processing and shaping, and is a non-tensile component. The fabric of this structure is used as a cushioning layer in the conveyor belt to improve the fabric core conveyor belt And the impact and tear resistance of the steel cord conveyor belt. The twisted structure is divided into rigidity and flexibility. The weft material of the rigid structure is a thin steel wire rope with a diameter of 1.5 to 2.0 mm, and its single breaking strength is 1.5 to 3.7. The weft material of the flexible structure is a high-strength and high-stretch nylon cord with a diameter of 1.5~4.0mm, single breaking strength is 1.2~4.5kN, and the breaking elongation is greater than 25%. The warp materials of these two structures are both nylons.

Steel Cord

The steel cord used in the conveyor belt is made of high-grade carbon steel, the diameter of the steel wire is 0.2~1.0mm, the tensile strength is 1,800-2600MPa, the surface is galvanized and rust-proof, and it has the function of strengthening the bonding of the steel wire and rubber. The structure of the steel cord is mostly 7-strand type, the basic unit is steel wire, the steel wire is twisted into strands, and multiple strands are arranged in a spiral to twist into a rope. The rope diameter is 2.0 to 14.0mm, the breaking strength of a single steel wire is 3.7 to 175kN, and the structure has 7×7, 7×12, 7×19, 7×31, and other varieties. The steel cord composed of multiple steel wires ensures high flexibility at low elongation. The requirements for the steel cord are the smallest possible diameter and the highest possible strength, as well as a strong galvanized layer and an open structure. The open structure facilitates the penetration of core rubber.

This is an amazing blog related to the structure of material about belt conveyors. It is helpful for those who are looking for this information. Well done!