Conveyor belt vulcanization process and precautions

During the vulcanization process of the conveyor belt, the control of vulcanization temperature and pressure is a key issue. If the temperature is too high, the rubber will heat up too quickly, the temperature difference between the inside and outside will be too large, the inner core rubber has not been fully vulcanized, and the […]

The Roles of Textiles in Conveyor Belting

The role of carcass is to withstand the forces from the inside and outside of the rubber conveyor belt, improve the strength of the rubber belt, and limit its deformation. It largely determines the performance, service life and use value of rubber conveyor belt. The carcass is made of textile fiber (including natural fiber and […]

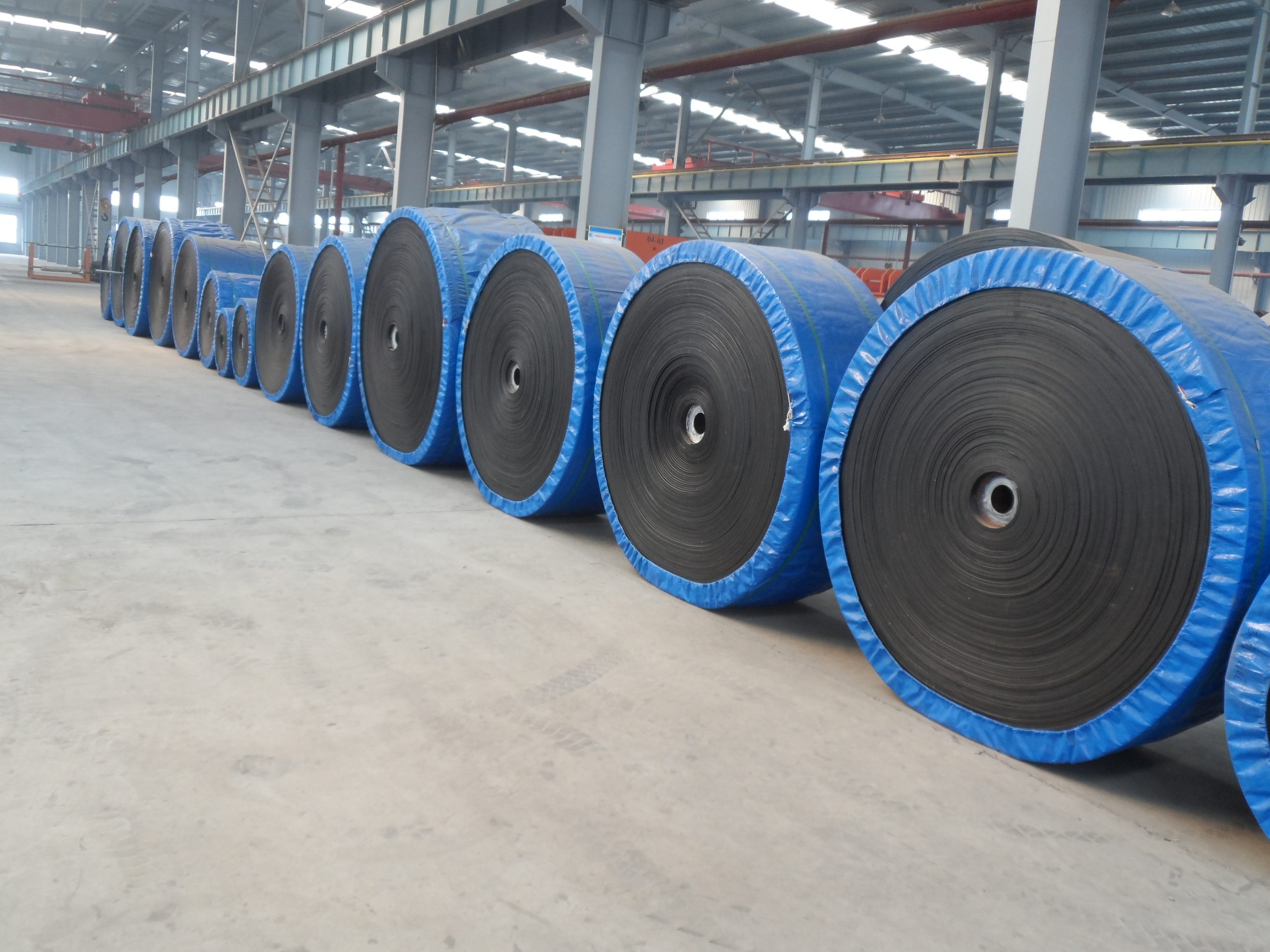

Abrasion-Resistant Rubber Conveyor Belts

Abrasion-Resistant Rubber Conveyor Belts We produce high-quality abrasion-resistant rubber conveyor belts perfect for airports, steel plants, mining companies, shipyards, cement companies, thermal power plants and many other industries. Our belts are precision engineered and can move cullet, glass,granite, trap rock, bulk products and any abrasive materials. No matter your industry or application, we have the […]

The relationship between ozone and conveyor belt aging

Ozone is an important factor that causes the rubber conveyor belt to age in the atmosphere. Ozone is more active than oxygen, and its attack on conveyor belts, especially unsaturated rubber, is much more serious than oxygen. After the oxygen molecules absorb short-wave ultraviolet light in the sunlight, the decomposed oxygen atoms recombine with the […]

How To Track A Conveyor Belt?

Conveyor belt tracking is the process of making sure the belt is properly aligned and controlled so it continues to maintain the desired path. The process does not have to be very difficult. There are some easy, helpful tips you can use to get and keep your conveyor belt running smoothly. The factors influencing the […]

Why use a conveyor belt?

Why can conveyor belts be widely used in various industries instead of labor? Because conveyor belts have advantages that cannot be achieved by humans. The conveyor belt has high efficiency and low error, which can save manpower and material resources for the enterprise. Compared with traditional human material transportation, conveyor belts have more obvious advantages. […]

Common types of conveyor belts and notice for use and maintenance

The component of Conveyor Belts Carcass, Cover rubber, Skim rubber, Edge rubber carcass:is the key component of the conveyor belt, it defines the tensile strength of the belt, and absorbs the impact from materials. skim rubber:bond the carcass layer, prevent the delamination of the carcass layer cover rubber:protect the carcass, transfer the power, absorbs the […]

How to use the conveyor belts correctly?

Prevent the conveyor belt from starting under load. If the conveyor belt deviates, measures should be taken to correct it in time. Conveyor belts of different types and specifications are not suitable to be connected together, and the joints should preferably be vulcanized. Select the right type, structure, specification and number of layers of the […]

How to maintain the vulcanized joint of steel cord conveyor belt?

Steel cord conveyor belt has the advantages of high tensile strength, low elongation, flexural fatigue resistance, superior impact resistance, and long service life, so it has been widely used in factories and mines. Especially in the main underground transportation system of coal mines, steel cord conveyor belts are mostly used on belt conveyors with high […]

Features of conveyor belt press vulcanizing machine

Conveyor belt press vulcanizing machine is mainly used for vulcanizing flat belts, rubber sheets, polymers and other products. It has the advantages of high pressure per unit area of the hot plate, reliable operation of the equipment, and less maintenance. The main function of the plate vulcanizer is to provide the pressure and temperature required […]

Appearance defects of heat-resistant conveyor belts

Heat-resistant conveyor belt uses different types of raw rubber, and the product appearance quality are different, and the appearance defects of different rubber types are not same. The following are several varieties of rubber materials we commonly use. SBR: SBR is the most commonly used rubber material for heat-resistant belts. Compared with the EPR and […]

How to identify the quality of rubber conveyor belts?

The rubber conveyor belt is a vital part of the entire conveyor system. The quality of the conveyor belt is directly related to the manufacturer’s normal production and may cause major safety accidents. A good quality rubber conveyor belt should be both in appearance and internal quality. Very good, here is a brief introduction to […]

Why does the conveyor belt slip?

Why does the conveyor belt slip? The initial tension is too small. The tension at the separation point of the belt and the roller is not enough. This situation generally occurs at startup. The friction between the roller and the conveyor belt is not enough. The reason for this is most likely that there is water on […]

Joint methods of conveyor belt

All conveyor belts must be connected in a circle shape before they can be used, so the quality of the conveyor belt joints directly affects the service life of the conveyor belt and the smooth operation of the conveyor line. Commonly used methods for conveyor belt joints include mechanical joints, cold-bonded joints, and hot vulcanized […]

Classification of heat resistant conveyor belts

Heat resistant conveyor belts are divided into ordinary heat-resistant conveyor belts and strong heat-resistant conveyor belts. The strength layer of ordinary heat-resistant belts is polyester cotton canvas (CC56), and the strength layer of strong heat-resistant belts is EP (specifically, it is divided into EP100 and EP150. , EP200, EP250, EP300, EP350, EP400, etc.). Mainly used […]

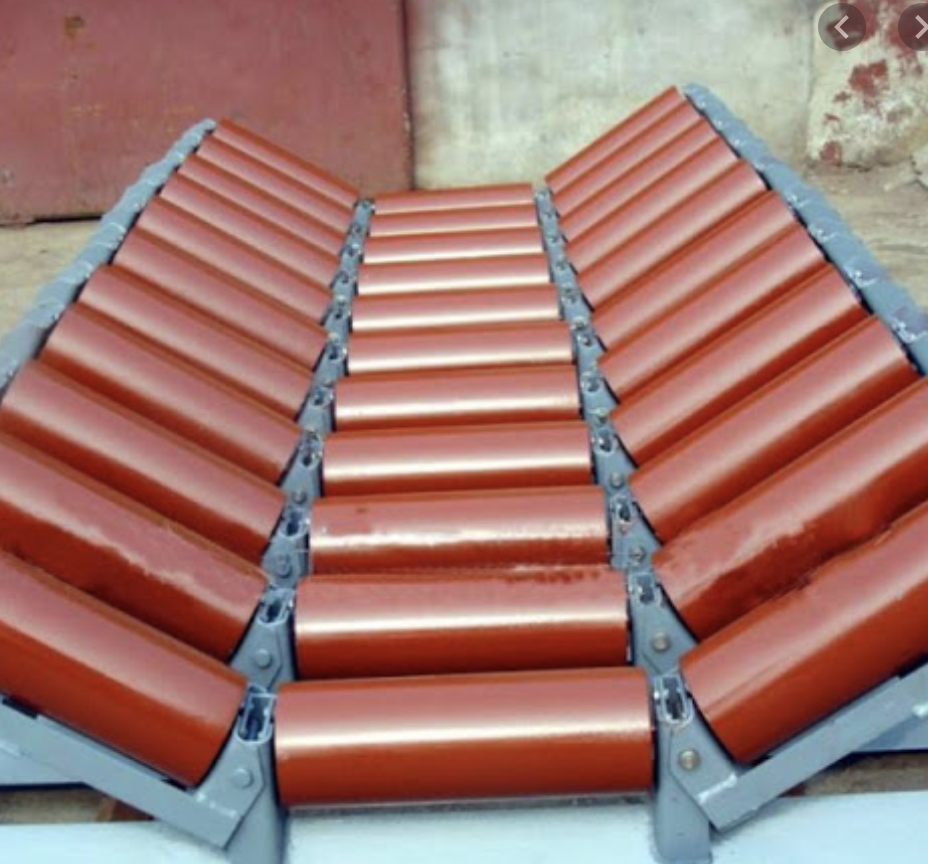

The important part that affects the life of the conveyor belt—the roller/idler

As an important device of a belt conveyor, the cost of a conveyor roller accounts for 35% of a belt conveyor and bears at least 70% of the resistance of the conveyor, so the quality of the roller is very important.