Description

Usage

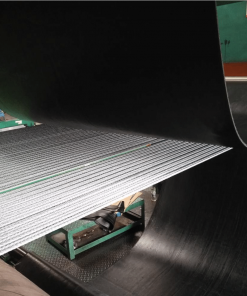

Combined with high strength, lightweight materials and multifunction cover materials, the

An aramid conveyor belt is suitable for various application areas.

Characteristics

Low energy consumption

The structure of straight warp and straight weft consists of aramid cords in warp and nylon cord in weft on both sides which will protect the belt. The lightweight aramid conveyor belt can reduce the power consumption of the conveyor. It will save more energy by using energy-saving rubber with low rolling resistance as the pulley side.

Impact resistance

As the toughness of aramid fabric can protect the conveyor belt from being punctured by sharp conveying materials. It can also reduce the damage of the conveyor belt even if in high drop distance.

High heat resistance and flame resistance

High heat resistance property will protect the conveyor belt from being damaged by conveying materials with high temperature. Even the burning substance is not easy to penetrate the aramid core

Anti-corrosion

Aramid, as the man-made fabric itself is superior resistant to media. Otherwise, it has excellent properties in chemical resistance and corrosion resistance.

Optimized belt design for a long lifetime

As there’s single fabric ply only, the carcass is light and flexible with optimum strength utilization. Aramid conveyor belts are excellent in fatigue resistance throughout their lifetime. Top and bottom cover meet high demands on wear and impact resistance, which provides the optimum protection for the valuable aramid.