Description

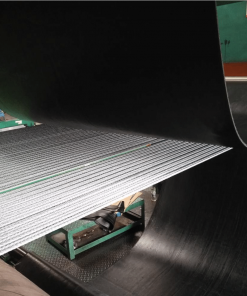

Oil Resistant Conveyor Belt for vegetable and animal oils, fats application

Rubber swells and distorts as a result of oil penetration. This causes severe tracking and steering issues, as well as early belt wear and, eventually, total belt failure. These harmful oils, fats, and greases come from two different sources: mineral and vegetable/animal.

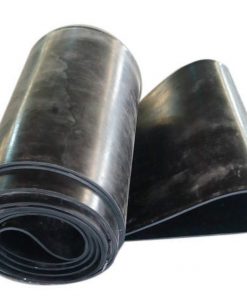

EP (polyester/nylon) is used as the carcass material for the oil-resistant conveyor belt. It has high strength, low stretch, good adhesion, and great rip and tear resistance. The surface material for the covering layer is nitrile butadiene rubber (NBR). For the covering layer of oil-resistant rubber conveyor belts, NBR is the finest option.

- The MOR type oil-resistant conveyor belt’s cover is constructed of a unique SBR and nitrile butadiene rubber (NBR) polymerization, which provides excellent mineral oil resistance and great abrasion resistance.

Grain, rubbish, recycled waste, wood pulp, and pine are examples of materials with a modest oil content.

By reducing oil penetration and avoiding the gradual breakdown of the belt, the MOR type rubber belt cover extends its service life and minimizes maintenance.

- The OR type oil-resistant conveyor belt’s cover is constructed of NBR, which is suited for transporting mineral oil-containing items including grain, waste, oiled fertilizer, coated coal/coke, and other commodities.

Physical and Mechanical Properties of Rubber Cover:

| Type | Tensile Strength/Mpa | Breaking elongation/% | Abrasion loss/

mm3 |

| LO | ≥14.0 | ≥350 | ≤200 |

| DO | ≥16.0 | ≥350 | ≤160 |

| Note:LO-conveyor belt used in general working conditions;

DO-conveyor belt used in high abrasion & oil working conditions. |

|||

Oil Resistant Properties of Rubber Cover:

| Serial number | Test conditions of soak liquid | Volume change rate/%≤ | |||

| Oil number in GB/T1690 | Soak temperature/℃ | Soak time/h | LO | DO | |

| 1 | #2 oil | 70±2 | 70 +0/-1 | +20 | -5 |

| 2 | #3 oil | 70±2 | 70 +0/-1 | +50 | +5 |

| 3 | #3 oil | 100±2 | 22±0.25 | +50 | +5 |

| Note:You only need to choose one of the above three methods. | |||||